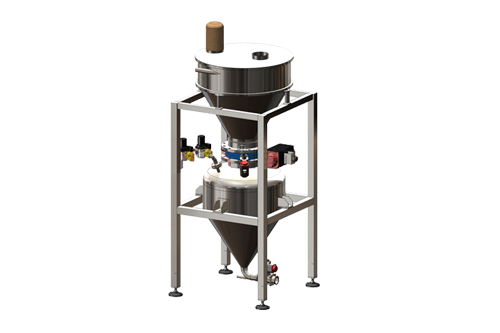

Dense phase pneumatic conveying systems are used when the product quality is of the highest importance. They minimise changes in bulk density and particle size distribution and also limit demixing effects, and can be used for many materials such as powders, granules, flakes and pellets.

The absence of rotating parts in pressure vessels reduces maintenance costs. The advantageous ratio of product to conveying gas also makes our systems energy efficient.

Specifications

| Model | ADC-100 | ADC-150 | ADC-200 |

| Delivery Pressure | 0.05~0.3Mpa | ||

| Air Consumption | 0.5~0.8Mpa about500L/min | ||

| Conveying Capacity | approximately1m³/h | approximately1.5m³/h | approximately2m³/h |

| Sending Tank Volume | 100L | 150L | 200L |

| Temporary Storage Bucket (optional) | 200L | ||

| Inlet Size | DN200(Φ219) | DN250(Φ273) | DN250(Φ273) |

| Outlet Size | Φ51 | Φ63 | Φ63 |

| Frame Size

(Including temporary storage bucket) |

820×820×2200 | 920×920×2200 | 920×920×2200 |

Common Applications

Breadcrumb

Brown-Sugar

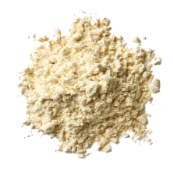

Cake-Mix

Cat Litter

Cement-Powder

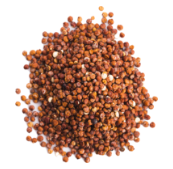

Chia-Seeds

Cocoa-Powder

Cosmetics Powder

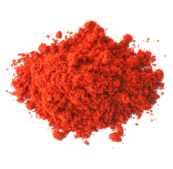

Curry-Powder

Detergent-Powder

Fennel Grass-Seeds

Food Powders

Grains

Ground Spices

Infant Formula

Jimmies Sprinkles

Lentils-Seeds

Matcha-Powder

Pancake-Mixpng

PepperGround Pepper

Plant Foods

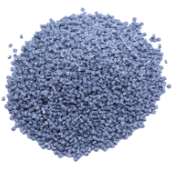

Plastic Granules

Protein-Powder

Rice-Powder

Salt-Products

Seeds

small Pet Food

Sugar

Toner Powder

Turmeric-Spices

wholeGround-coffee

Milk Powder